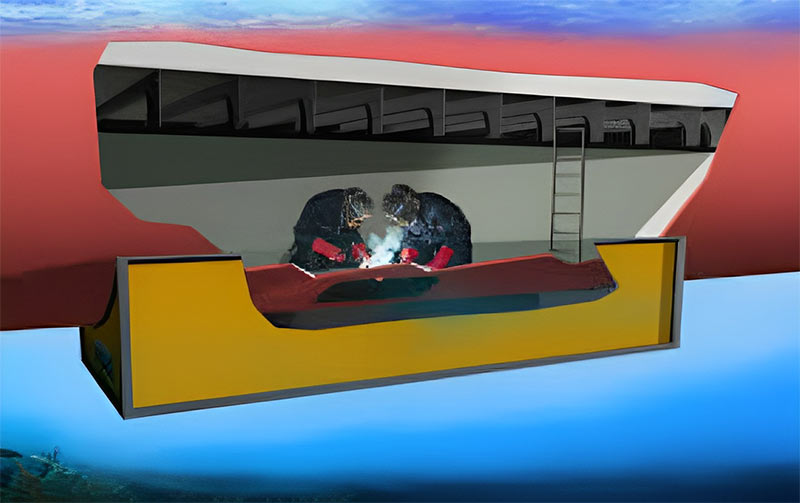

Cofferdams are commonly constructed using steel sheet piles driven into the seabed.

“These interlocking sheets circle the repair area and are sealed with packed clay or concrete,”

“We then pump out the water so our divers can access the dry, sealed space.”

– Explains a Senior Commercial Diver at Trident.

Once the cofferdam is installed, divers conduct detailed inspections and require repairs ranging from small corrosion patches to shaft replacements. Hoses provide air and electricity, while suction hoses remove debris and sediment.

Trident, with its extensive experience in underwater maintenance, ensures that every aspect of the repair work adheres to the highest standards of safety and efficiency. Our divers are equipped with state-of-the-art tools and follow a meticulous process to ensure thorough inspections and precise repairs.

Image courtesy of Hydrex

For minor routine repairs, cofferdam installation is far more economical than dry docking enormous vessels. “It eliminates the need to transport ships to a different facility. Repairs can be completed right at the dock,” says Tan. Cofferdams also take days rather than weeks to install compared to dry docks.

By choosing Trident, clients are assured of a service that combines technical excellence with a commitment to environmental sustainability. We employ eco-friendly practices in all our operations, minimizing the impact on marine ecosystems while delivering exceptional results.

Let our hull cleaning experts keep your ships sailing at peak performance all year

Copyright © Trident 2024. All rights reserved / Powered by Rezult.co