Trident offers cutting-edge inspection solutions for a wide range of industrial applications, including pipes, confined spaces, aerial structures, and more. Our advanced technologies deliver precise, reliable results for even the most complex inspection needs.

We prioritize safety and efficiency in confined space inspections by leveraging

state-of-the-art drone and robotic technologies. This innovative approach

minimizes the need for human entry into high-risk environments, reducing

exposure to safety hazards. Drones provide high-resolution imagery and real-time

data, ensuring thorough, accurate, and non-invasive inspections that are both cost effective and efficient. By addressing the unique challenges of confined space

inspections, we deliver comprehensive solutions that prioritize safety, precision,

and minimal disruption to your operations. Our inspection capabilities cover a wide

range of locations, including:

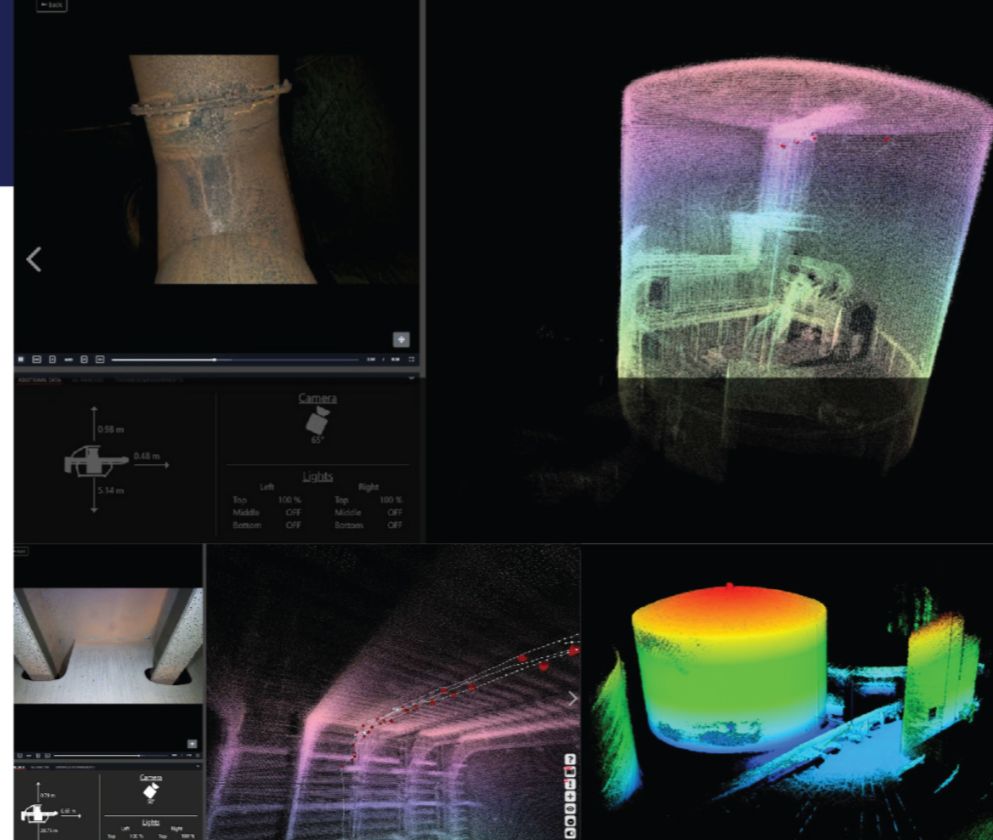

We utilize cutting-edge drone technologies to enhance the accuracy and efficiency of our inspections. Our services include:

By integrating these advanced technologies with our expertise, we deliver high-resolution imagery, real-time data, and comprehensive insights, significantly reducing the reliance on manual labor in hazardous environments.

Detects temperature variations to identify issues such as heat loss, electrical faults, or leaks, even in hard-to-reach areas. This non-invasive method helps pinpoint problems early, preventing costly repairs.

Provides highly accurate 3D mapping and detailed measurements of structures, terrain, and environments. LiDAR can capture surface thickness and other essential data for precise analysis and planning.

By combining these advanced technologies with our expertise, we provide highresolution imagery, real-time data, and comprehensive insights, minimizing the

need for manual labor in hazardous environments.

Our ROVs (Remotely Operated Vehicles) are revolutionizing underwater inspections

by providing a safe, efficient, and non-invasive solution for various submerged

structures. These advanced technologies allow for precise inspections without the

need for human entry into hazardous environments, minimizing risks and reducing

downtime.

Trident is dedicated to delivering advanced inspection solutions for industrial and marine applications. Our commitment to innovation and safety ensures your assets are maintained to the highest standards, maximizing their operational life and performance.

Copyright © Trident 2024. All rights reserved / Powered by Rezult.co